Sunday, February 19, 2006

Wednesday, February 15, 2006

I haven't had much opportunity to shoot lately nor pursue my other shooting related hobbies including reloading. One thing I have been able to do is to follow the news. The story about the Vice President of the USofA, Dick Cheney, accidentally shooting one of his quail hunting party has been front and center this week. Hard to avoid hearing or seeing this on radio, TV and the internet in blogs and forums, I've had some thoughts I'd like to share.

First thing when I heard of the incident, I prayed for all involved. It is my fervent hope that both the VP and his hunting buddy Mr. Whittington and their families come through this without problems. I also hope that we learn the intended lessons from this "event".

This sort of thing is something that no shooter wants to happen. Most of us take extreme measures in our attempts to ensure that such things don't happen. We don't want to hurt others, we don't want to be embarrassed by our lack of skill, we don't want to be sanctioned by society, we want to continue to hunt, we don't want to lose the opportunity for camaraderie that exists in such hunts and we are generally among the most responsible people in society. I doubt that the VP is any different from any of the rest of us.

Most of us who've been hunting over broken terrain with lots of low vegetation like a cornfield realize that a number of circumstances/conditions can come together and often do to maximize risk. Party members becoming separated from the party and rejoining the party at an unexpected juncture (location and or time), sunlight impeding vision (particularly early in the morning or late in the day), terrain and vegetation obscuring visibility, all the movement of the various hunters, dogs, and perhaps dog handlers as well as flushing birds can come together to create a bad situation very quickly. Apparently, all these came together and the result was that one hunter shot another (the VP shot Mr. Whittington). Very unfortunate.

Fortunate though was that the VP's physician's assistant was there and immediately treated Mr. Whittington. Unfortunately Mr. Whittington (age 78) has suffered some complications with a pellet apparently traveling to the heart muscle and causing a minor heart attack. He remains in the hospital.

The news reporters have been singularly unhelpful in understanding the situation. They are simply too ignorant to use the proper terminology in describing the incident and have used inaccurate terms such as "buckshot" and inflammatory but imprecise terms like "sprayed with shot" (or "buckshot") which do nothing to understand the incident. It seems too that nobody can get the distance nailed down. Was Mr. Whittington 30 yards or 30 feet from the VP when shot? The VP says 30 yards.

Perhaps the most important thing to the news people isn't that there was an accidental shooting but that the Corpus Christi newspaper was able to scoop them. How does this help provide information to the public? In fact, the major media may have contributed to this by making the VP "gun shy" (I couldn't resist) because they don't trust anything he says.

Then the Democrats have been leaping on the bandwagon as well accusing the administration of being secretive and even Ted Kennedy has wondered aloud why it took so long to release the information to the public. Of course Mr. Whittington survived, Mary Jo Kopechne is in her grave because Teddy left her in the car in the water to die. Hypocrisy is everywhere but it isn't surprising.

The informal networks of shooters have had a field day with the subject. Detailed analysis of the shooting based on the very little information provided has been incessant. A lot of it seems to be more intended to give the writer or speaker an opportunity to expound than for any other reason (HEY!, this IS my blog). One of the big things that some folks have seized on for discussion was that both the VP and Mr. Whittington (although he is seldom mentioned) did not have a particular license newly required by Texas for quail hunting.

I read one forum poster say that the VP was a poacher because he failed to get a license that had never before been required. He ignored the reported fact that both the person purchasing the stamp/tag/license for Mr. Cheney and the Texas seller of that stamp/tag/license (reported several times as being a member of the Texas department responsible for the regulations and enforcement) failed to realize that the stamp/tag/license was required. If the expert doesn't know you need the stamp/tag/license how can you get upset that the VP doesn't know? Mr. Whittington didn't have the stamp/tag/license either! Sounds to me as though the state of Texas needs to do some education on the subject. I don't think "poacher" applies since BOTH hunters made every attempt to have the correct licenses. Poachers actively avoid licensing.

The posters were also upset that these folks were given "preferential treatment" as they only had to buy the missing stamp/tag/license. Sounds like common sense enforcement to me. These same folks were upset that the VP had somebody else buy his license for him, as though that was some sort of elitism. That amazed me as it is common here in VA. It is also common that the buyer fails to purchase a particular tag but it isn't so complicated that most folks can catch the error before going afield. Changes are one thing that catches many folks. The VADGIF sees fit to move the seasons about and change the license and terms enough to confuse even long time hunters and it certainly is easier here than elsewhere.

Others were upset that the VP wasn't in jail for the shooting. Apparently, the Texas and local law enforcement folks acted within the law. So what is wrong with that? Would any of these folks finding themselves in the same unfortunate circumstance DEMAND that they themselves be jailed? I doubt it. In my mind the actions of the Texas state and/or local law enforcement officials acted as they should act in every such case.

Now we've heard from the VP in an interview with Brit Hume of Fox News Channel. Mr. Cheney clearly explains the actual events of the incident. He accepts responsibility even though there were circumstances which clearly contributed to the accident.

What it has come down to is politics and hate. There are folks who will say and do anything however falsely to politically hurt the VP and President. There are folks who simply hate and distrust these men without reasonable cause. This is more than unfortunate.

First thing when I heard of the incident, I prayed for all involved. It is my fervent hope that both the VP and his hunting buddy Mr. Whittington and their families come through this without problems. I also hope that we learn the intended lessons from this "event".

This sort of thing is something that no shooter wants to happen. Most of us take extreme measures in our attempts to ensure that such things don't happen. We don't want to hurt others, we don't want to be embarrassed by our lack of skill, we don't want to be sanctioned by society, we want to continue to hunt, we don't want to lose the opportunity for camaraderie that exists in such hunts and we are generally among the most responsible people in society. I doubt that the VP is any different from any of the rest of us.

Most of us who've been hunting over broken terrain with lots of low vegetation like a cornfield realize that a number of circumstances/conditions can come together and often do to maximize risk. Party members becoming separated from the party and rejoining the party at an unexpected juncture (location and or time), sunlight impeding vision (particularly early in the morning or late in the day), terrain and vegetation obscuring visibility, all the movement of the various hunters, dogs, and perhaps dog handlers as well as flushing birds can come together to create a bad situation very quickly. Apparently, all these came together and the result was that one hunter shot another (the VP shot Mr. Whittington). Very unfortunate.

Fortunate though was that the VP's physician's assistant was there and immediately treated Mr. Whittington. Unfortunately Mr. Whittington (age 78) has suffered some complications with a pellet apparently traveling to the heart muscle and causing a minor heart attack. He remains in the hospital.

The news reporters have been singularly unhelpful in understanding the situation. They are simply too ignorant to use the proper terminology in describing the incident and have used inaccurate terms such as "buckshot" and inflammatory but imprecise terms like "sprayed with shot" (or "buckshot") which do nothing to understand the incident. It seems too that nobody can get the distance nailed down. Was Mr. Whittington 30 yards or 30 feet from the VP when shot? The VP says 30 yards.

Perhaps the most important thing to the news people isn't that there was an accidental shooting but that the Corpus Christi newspaper was able to scoop them. How does this help provide information to the public? In fact, the major media may have contributed to this by making the VP "gun shy" (I couldn't resist) because they don't trust anything he says.

Then the Democrats have been leaping on the bandwagon as well accusing the administration of being secretive and even Ted Kennedy has wondered aloud why it took so long to release the information to the public. Of course Mr. Whittington survived, Mary Jo Kopechne is in her grave because Teddy left her in the car in the water to die. Hypocrisy is everywhere but it isn't surprising.

The informal networks of shooters have had a field day with the subject. Detailed analysis of the shooting based on the very little information provided has been incessant. A lot of it seems to be more intended to give the writer or speaker an opportunity to expound than for any other reason (HEY!, this IS my blog). One of the big things that some folks have seized on for discussion was that both the VP and Mr. Whittington (although he is seldom mentioned) did not have a particular license newly required by Texas for quail hunting.

I read one forum poster say that the VP was a poacher because he failed to get a license that had never before been required. He ignored the reported fact that both the person purchasing the stamp/tag/license for Mr. Cheney and the Texas seller of that stamp/tag/license (reported several times as being a member of the Texas department responsible for the regulations and enforcement) failed to realize that the stamp/tag/license was required. If the expert doesn't know you need the stamp/tag/license how can you get upset that the VP doesn't know? Mr. Whittington didn't have the stamp/tag/license either! Sounds to me as though the state of Texas needs to do some education on the subject. I don't think "poacher" applies since BOTH hunters made every attempt to have the correct licenses. Poachers actively avoid licensing.

The posters were also upset that these folks were given "preferential treatment" as they only had to buy the missing stamp/tag/license. Sounds like common sense enforcement to me. These same folks were upset that the VP had somebody else buy his license for him, as though that was some sort of elitism. That amazed me as it is common here in VA. It is also common that the buyer fails to purchase a particular tag but it isn't so complicated that most folks can catch the error before going afield. Changes are one thing that catches many folks. The VADGIF sees fit to move the seasons about and change the license and terms enough to confuse even long time hunters and it certainly is easier here than elsewhere.

Others were upset that the VP wasn't in jail for the shooting. Apparently, the Texas and local law enforcement folks acted within the law. So what is wrong with that? Would any of these folks finding themselves in the same unfortunate circumstance DEMAND that they themselves be jailed? I doubt it. In my mind the actions of the Texas state and/or local law enforcement officials acted as they should act in every such case.

Now we've heard from the VP in an interview with Brit Hume of Fox News Channel. Mr. Cheney clearly explains the actual events of the incident. He accepts responsibility even though there were circumstances which clearly contributed to the accident.

What it has come down to is politics and hate. There are folks who will say and do anything however falsely to politically hurt the VP and President. There are folks who simply hate and distrust these men without reasonable cause. This is more than unfortunate.

Saturday, February 04, 2006

The Taylor's & Co. Spencer carbine as shown on their website

Guns magazine has a good, Taylor's & Company .56-50 Spencer carbine article by Mike Venturino. This rifle might be quite a bit of fun. However, there are others we'd like to have...

Chaparral Arms is coming out with a reproduction of the Winchester 1876. They will also be producing ammunition. This is particularly important so far as the .45-75 is concerned.

The Winchester 1876 Reproductions as shown on the Chaparral Arms website

Taurus has announced and actually released, I've handled one, the Thunderbolt. A .357 Magnum or .45 Colt rifle based on the Colt Lightning, this pump action gun is light, seems to have good handling characteristics, and is pretty exciting for those of us who can't afford the more historically correct USFA version.

The Taurus Thunderbolt as shown on the Taurus website

Thursday, February 02, 2006

Rifle Sights - part 1

Recent forum discussions gave me the idea that I might like to set down my ideas on rifle sights. I've got strong prejudices/preferences just as many other folks do and I think it should be helpful to articulate those thoughts.

Because so many folks kid me about it I suppose that my liking/preference for the Williams Foolproof receiver sights is well known. I like it because although the Foolproof is made of aluminum it is sturdy, simple, and has no "extra" parts to come undone. I'm a big supporter of the KISS principle. It is also light and the finish is durable. Even in today's world of sometimes sloppy or overseas manufacturing, these sights are made in the USofA and consistently well done.

Because so many folks kid me about it I suppose that my liking/preference for the Williams Foolproof receiver sights is well known. I like it because although the Foolproof is made of aluminum it is sturdy, simple, and has no "extra" parts to come undone. I'm a big supporter of the KISS principle. It is also light and the finish is durable. Even in today's world of sometimes sloppy or overseas manufacturing, these sights are made in the USofA and consistently well done.

Williams also makes the 5D sight. This sight isn't as sophisticated as the Foolproof in that it doesn't have click adjustments. One simply loosens the lock-down screws and slides the sight about to adjust. With practice this can be easy and for those who never feel a need to rezero for any reason (especially if you only shoot one load), this sight will suffice. You'll note that it looks very much like the Foolproof and the sight bases (the part that attaches to the rifle) are, in fact, the same. The biggest advantage this sight has over the Foolproof is price. Normally you can get it for a little over one-half the price of a Foolproof from the same vendor.

Williams also makes the 5D sight. This sight isn't as sophisticated as the Foolproof in that it doesn't have click adjustments. One simply loosens the lock-down screws and slides the sight about to adjust. With practice this can be easy and for those who never feel a need to rezero for any reason (especially if you only shoot one load), this sight will suffice. You'll note that it looks very much like the Foolproof and the sight bases (the part that attaches to the rifle) are, in fact, the same. The biggest advantage this sight has over the Foolproof is price. Normally you can get it for a little over one-half the price of a Foolproof from the same vendor.

Williams makes yet another receiver sight, the Guide Receiver sight. As you can see this doesn't mount to the side of the rifle but to the top of the receiver or barrel. The weakness of this sight is primarily in the range of available adjustment. As you can see in the photos, both windage and elevation adjustment is very limited when compared to the Foolproof and 5D. The Guide Receiver Sight is nothing more than an adaptation of the Guide Open Sight with an aperture. Very clever are those engineers at Williams Gunsights. The Guide Sight has one or two advantages. The first is price over the Foolproof. The second is subjective and is that the base on the side of the rifle is eliminated providing a "cleaner" look.

Williams makes yet another receiver sight, the Guide Receiver sight. As you can see this doesn't mount to the side of the rifle but to the top of the receiver or barrel. The weakness of this sight is primarily in the range of available adjustment. As you can see in the photos, both windage and elevation adjustment is very limited when compared to the Foolproof and 5D. The Guide Receiver Sight is nothing more than an adaptation of the Guide Open Sight with an aperture. Very clever are those engineers at Williams Gunsights. The Guide Sight has one or two advantages. The first is price over the Foolproof. The second is subjective and is that the base on the side of the rifle is eliminated providing a "cleaner" look.

A Williams Guide Receiver Sight mounted on an NEF rifle. Courtesy of Junior Doughty

I've never had any problems with the Williams sight save one. When I buy them used they sometimes come minus the mounting screws. A quick call or letter to Williams gets a set of screws for that particular sight.

Then there is the Lyman series of sights. Lyman has been making tang and receiver sights for a LONG time. It is very interesting to look at the evolution of the aperture sight as built by Lyman as it begins with simple tang sights and the muzzleloader era to sophisticated click adjustable receiver sights and from all steel to aluminum. However, I'm going to limit myself to sights I'd use for pump and lever action rifles.

I actually started with a Lyman #2 tang sight on the Winchester M62A shown in the photo. This was actually the very first rimfire I ever shot! This isn't the best photo, but I have one old Lyman and one new Marbles mounted on my Winchester pump action .22 rifles. These sights are pretty good and practical on the .22s.

I actually started with a Lyman #2 tang sight on the Winchester M62A shown in the photo. This was actually the very first rimfire I ever shot! This isn't the best photo, but I have one old Lyman and one new Marbles mounted on my Winchester pump action .22 rifles. These sights are pretty good and practical on the .22s.

The tang sights are fine for soft recoiling firearms and they do increase the sight radius over that possible with the receiver sights but I can't say that I (that's me, some folks don't have these problems) like them for heavier recoiling for a couple of reasons. First, since they sit on the tang they tend to slide by the hand while not permitting the same grip one would take on the gun's wrist if they weren't there. This can result in distracting abrasions. Second, the tang sight sits awfully close to the eye and it does make me a bit nervous in the prone position (I think prone is a bit more likely circumstance than using high angle fire with a big-bore rifle).

The tang sights are fine for soft recoiling firearms and they do increase the sight radius over that possible with the receiver sights but I can't say that I (that's me, some folks don't have these problems) like them for heavier recoiling for a couple of reasons. First, since they sit on the tang they tend to slide by the hand while not permitting the same grip one would take on the gun's wrist if they weren't there. This can result in distracting abrasions. Second, the tang sight sits awfully close to the eye and it does make me a bit nervous in the prone position (I think prone is a bit more likely circumstance than using high angle fire with a big-bore rifle).

However, the Lyman sight I'm most likely to have use of is the 66. The 66LA is the sight intended for the Winchester and Marlin lever actions. It looks very much like the WB sight which is for the Winchester 1886 lever action. Although these were once made of steel, they are now aluminum.

I have a Lyman. I got it for and it is mounted on my 336T. The Lyman's have the ability to be zeroed out so that one can adjust from a known point and back again. this should be an advantage over the Williams. Unfortunately the system used is a separate sliding plate(s) retained by screw(s). You can see the elevation plate in the above photo. In my "lemon" the elevation plate screw stripped the threads on the aluminum base. As machinists know, not all alloys are created equal and the Lyman aluminum alloy is apparently NOT the equal of the alloy used in the Williams sights. Perhaps, too, the tap and or drill weren't correct and the hole slightly oversize.

I have a Lyman. I got it for and it is mounted on my 336T. The Lyman's have the ability to be zeroed out so that one can adjust from a known point and back again. this should be an advantage over the Williams. Unfortunately the system used is a separate sliding plate(s) retained by screw(s). You can see the elevation plate in the above photo. In my "lemon" the elevation plate screw stripped the threads on the aluminum base. As machinists know, not all alloys are created equal and the Lyman aluminum alloy is apparently NOT the equal of the alloy used in the Williams sights. Perhaps, too, the tap and or drill weren't correct and the hole slightly oversize.

When I contacted Lyman (who do nothing via e-mail or so it seems, a definite no-no in today's market) I was basically told tough luck. No offer to make it right, nothing. So, I simply adjusted the sight and epoxied the plate in place. Otherwise there was nothing wrong with the sight. The Lyman 66LA costs about the same as the Williams Foolproof. It is click adjustable and some folks prefer the small knobs (one could buy a Williams Foolproof with the Target Knobs option which is more expensive). I think the biggest advantage the Lyman has over the Foolproof is the plunger which is a quick release which allows the bar to be removed from the base and returned to zero. The Foolproof can't do that.

The Lyman and other receiver sights made of steel including the Redfields are to be preferred if only because they are nostalgic. There is just something special about a steel sight. There are many who believe that a steel sight is more durable than any aluminum sight.

The Lyman and other receiver sights made of steel including the Redfields are to be preferred if only because they are nostalgic. There is just something special about a steel sight. There are many who believe that a steel sight is more durable than any aluminum sight.

For many years, most models of guns were drilled and tapped for receiver or tang sights. It was no great thing to mount one of these, go zero it and then go hunting. A new front sight was seldom required. Now, one must have the side of the receiver drilled and tapped by a gunsmith at up to $50 a hole (when you can't do it yourself). Is it any wonder that popularity of the aperture sight has declined?

There are some who say that the Lyman and Williams sights are prone to snag (snag what, how?) or bend or get knocked off and they prefer other systems. I personally don't know anything that snags stuff more than a scope sight or tang sights. I suppose you could bend the horizontal bar but don't you have to work at it? Yes, I know one fellow that broke a Williams Foolproof off a Ruger M77. But look at the rest of his stuff, he beats the hell out of all of it!

There are other folks who make aperture sights. These are mostly like the Williams Guide Receiver Sight in concept in that they are mounted on top of the receiver. Most REQUIRE a new front sight and indeed, this is usually a part of the package. They have the same weaknesses and strengths of the WGRS. There are also specialty aperture sights made to mount on scope sight mounts as emergency replacements for scope sights. That has got to be a good idea.

As to scope sights for lever actions, well, they seem out of place to me. They negate the handling and compact characteristics of the leveractions that attracted me. If one must have a scope sight on a levergun I'd suggest as compact a scope as possible. I'd probably go for one of the Weaver 2½X fixed power scopes that I use on my Contender carbines.

Because so many folks kid me about it I suppose that my liking/preference for the Williams Foolproof receiver sights is well known. I like it because although the Foolproof is made of aluminum it is sturdy, simple, and has no "extra" parts to come undone. I'm a big supporter of the KISS principle. It is also light and the finish is durable. Even in today's world of sometimes sloppy or overseas manufacturing, these sights are made in the USofA and consistently well done.

Because so many folks kid me about it I suppose that my liking/preference for the Williams Foolproof receiver sights is well known. I like it because although the Foolproof is made of aluminum it is sturdy, simple, and has no "extra" parts to come undone. I'm a big supporter of the KISS principle. It is also light and the finish is durable. Even in today's world of sometimes sloppy or overseas manufacturing, these sights are made in the USofA and consistently well done. Williams also makes the 5D sight. This sight isn't as sophisticated as the Foolproof in that it doesn't have click adjustments. One simply loosens the lock-down screws and slides the sight about to adjust. With practice this can be easy and for those who never feel a need to rezero for any reason (especially if you only shoot one load), this sight will suffice. You'll note that it looks very much like the Foolproof and the sight bases (the part that attaches to the rifle) are, in fact, the same. The biggest advantage this sight has over the Foolproof is price. Normally you can get it for a little over one-half the price of a Foolproof from the same vendor.

Williams also makes the 5D sight. This sight isn't as sophisticated as the Foolproof in that it doesn't have click adjustments. One simply loosens the lock-down screws and slides the sight about to adjust. With practice this can be easy and for those who never feel a need to rezero for any reason (especially if you only shoot one load), this sight will suffice. You'll note that it looks very much like the Foolproof and the sight bases (the part that attaches to the rifle) are, in fact, the same. The biggest advantage this sight has over the Foolproof is price. Normally you can get it for a little over one-half the price of a Foolproof from the same vendor. Williams makes yet another receiver sight, the Guide Receiver sight. As you can see this doesn't mount to the side of the rifle but to the top of the receiver or barrel. The weakness of this sight is primarily in the range of available adjustment. As you can see in the photos, both windage and elevation adjustment is very limited when compared to the Foolproof and 5D. The Guide Receiver Sight is nothing more than an adaptation of the Guide Open Sight with an aperture. Very clever are those engineers at Williams Gunsights. The Guide Sight has one or two advantages. The first is price over the Foolproof. The second is subjective and is that the base on the side of the rifle is eliminated providing a "cleaner" look.

Williams makes yet another receiver sight, the Guide Receiver sight. As you can see this doesn't mount to the side of the rifle but to the top of the receiver or barrel. The weakness of this sight is primarily in the range of available adjustment. As you can see in the photos, both windage and elevation adjustment is very limited when compared to the Foolproof and 5D. The Guide Receiver Sight is nothing more than an adaptation of the Guide Open Sight with an aperture. Very clever are those engineers at Williams Gunsights. The Guide Sight has one or two advantages. The first is price over the Foolproof. The second is subjective and is that the base on the side of the rifle is eliminated providing a "cleaner" look.

A Williams Guide Receiver Sight mounted on an NEF rifle. Courtesy of Junior Doughty

I've never had any problems with the Williams sight save one. When I buy them used they sometimes come minus the mounting screws. A quick call or letter to Williams gets a set of screws for that particular sight.

Then there is the Lyman series of sights. Lyman has been making tang and receiver sights for a LONG time. It is very interesting to look at the evolution of the aperture sight as built by Lyman as it begins with simple tang sights and the muzzleloader era to sophisticated click adjustable receiver sights and from all steel to aluminum. However, I'm going to limit myself to sights I'd use for pump and lever action rifles.

I actually started with a Lyman #2 tang sight on the Winchester M62A shown in the photo. This was actually the very first rimfire I ever shot! This isn't the best photo, but I have one old Lyman and one new Marbles mounted on my Winchester pump action .22 rifles. These sights are pretty good and practical on the .22s.

I actually started with a Lyman #2 tang sight on the Winchester M62A shown in the photo. This was actually the very first rimfire I ever shot! This isn't the best photo, but I have one old Lyman and one new Marbles mounted on my Winchester pump action .22 rifles. These sights are pretty good and practical on the .22s. The tang sights are fine for soft recoiling firearms and they do increase the sight radius over that possible with the receiver sights but I can't say that I (that's me, some folks don't have these problems) like them for heavier recoiling for a couple of reasons. First, since they sit on the tang they tend to slide by the hand while not permitting the same grip one would take on the gun's wrist if they weren't there. This can result in distracting abrasions. Second, the tang sight sits awfully close to the eye and it does make me a bit nervous in the prone position (I think prone is a bit more likely circumstance than using high angle fire with a big-bore rifle).

The tang sights are fine for soft recoiling firearms and they do increase the sight radius over that possible with the receiver sights but I can't say that I (that's me, some folks don't have these problems) like them for heavier recoiling for a couple of reasons. First, since they sit on the tang they tend to slide by the hand while not permitting the same grip one would take on the gun's wrist if they weren't there. This can result in distracting abrasions. Second, the tang sight sits awfully close to the eye and it does make me a bit nervous in the prone position (I think prone is a bit more likely circumstance than using high angle fire with a big-bore rifle).However, the Lyman sight I'm most likely to have use of is the 66. The 66LA is the sight intended for the Winchester and Marlin lever actions. It looks very much like the WB sight which is for the Winchester 1886 lever action. Although these were once made of steel, they are now aluminum.

I have a Lyman. I got it for and it is mounted on my 336T. The Lyman's have the ability to be zeroed out so that one can adjust from a known point and back again. this should be an advantage over the Williams. Unfortunately the system used is a separate sliding plate(s) retained by screw(s). You can see the elevation plate in the above photo. In my "lemon" the elevation plate screw stripped the threads on the aluminum base. As machinists know, not all alloys are created equal and the Lyman aluminum alloy is apparently NOT the equal of the alloy used in the Williams sights. Perhaps, too, the tap and or drill weren't correct and the hole slightly oversize.

I have a Lyman. I got it for and it is mounted on my 336T. The Lyman's have the ability to be zeroed out so that one can adjust from a known point and back again. this should be an advantage over the Williams. Unfortunately the system used is a separate sliding plate(s) retained by screw(s). You can see the elevation plate in the above photo. In my "lemon" the elevation plate screw stripped the threads on the aluminum base. As machinists know, not all alloys are created equal and the Lyman aluminum alloy is apparently NOT the equal of the alloy used in the Williams sights. Perhaps, too, the tap and or drill weren't correct and the hole slightly oversize.When I contacted Lyman (who do nothing via e-mail or so it seems, a definite no-no in today's market) I was basically told tough luck. No offer to make it right, nothing. So, I simply adjusted the sight and epoxied the plate in place. Otherwise there was nothing wrong with the sight. The Lyman 66LA costs about the same as the Williams Foolproof. It is click adjustable and some folks prefer the small knobs (one could buy a Williams Foolproof with the Target Knobs option which is more expensive). I think the biggest advantage the Lyman has over the Foolproof is the plunger which is a quick release which allows the bar to be removed from the base and returned to zero. The Foolproof can't do that.

The Lyman and other receiver sights made of steel including the Redfields are to be preferred if only because they are nostalgic. There is just something special about a steel sight. There are many who believe that a steel sight is more durable than any aluminum sight.

The Lyman and other receiver sights made of steel including the Redfields are to be preferred if only because they are nostalgic. There is just something special about a steel sight. There are many who believe that a steel sight is more durable than any aluminum sight.For many years, most models of guns were drilled and tapped for receiver or tang sights. It was no great thing to mount one of these, go zero it and then go hunting. A new front sight was seldom required. Now, one must have the side of the receiver drilled and tapped by a gunsmith at up to $50 a hole (when you can't do it yourself). Is it any wonder that popularity of the aperture sight has declined?

There are some who say that the Lyman and Williams sights are prone to snag (snag what, how?) or bend or get knocked off and they prefer other systems. I personally don't know anything that snags stuff more than a scope sight or tang sights. I suppose you could bend the horizontal bar but don't you have to work at it? Yes, I know one fellow that broke a Williams Foolproof off a Ruger M77. But look at the rest of his stuff, he beats the hell out of all of it!

There are other folks who make aperture sights. These are mostly like the Williams Guide Receiver Sight in concept in that they are mounted on top of the receiver. Most REQUIRE a new front sight and indeed, this is usually a part of the package. They have the same weaknesses and strengths of the WGRS. There are also specialty aperture sights made to mount on scope sight mounts as emergency replacements for scope sights. That has got to be a good idea.

As to scope sights for lever actions, well, they seem out of place to me. They negate the handling and compact characteristics of the leveractions that attracted me. If one must have a scope sight on a levergun I'd suggest as compact a scope as possible. I'd probably go for one of the Weaver 2½X fixed power scopes that I use on my Contender carbines.

Wednesday, February 01, 2006

The .357 Remington Maximum in the Contender Carbine

I've was asked to write this short article on the .357 Remington Maximum as it applies to my Thompson Center Arms (www.tcarms.com) (TCA) Contender carbine. I thought that rather interesting as I often have written such articles in order to record the required data on my collection of firearms. So, this is written with the idea that I will forever be able to refer to it in the loading and shooting of that barrel.

THE GUN

My .357 Max is a factory, 21", blue, Contender purchased from the old TC Arms obsolete barrel list for $113.50 plus shipping. I like it. My thanks to all on the old TC-List for that tip. I don't know what the twist rate is, but I think it is the same as the .35 Rem, at least in the factory barrels.

I've mounted a Weaver 2½X fixed power scope in a Leupold mount. This scope has a duplex reticule. Now some may wonder at the low magnification of this scope but it suites me. Given the cartridge's capabilities, there is no need for more magnification.

It is stocked in factory Rynite. Rynite is a synthetic stock material and the stocks are made by Choate Machine and Tool Company (www.riflestock.com) for Thompson Center Arms. I like the combination of appearance (I'm used to synthetics from my military service) and light weight compared to wood. I also think that the Rynite stocks fit me better than the wood provided by TCA. Thus the gun all up (sling TOO) and loaded weighs just 6¼ lbs. That's not too much to pack for anyone.

As I write this I have 21 barrels of which only 2 are the 10" length. All others are 16" and longer and the cartridges for which they are chambered range from the .22 LR to 28 gauge shotgun. This barrel, chambered for the .357 Remington Maximum, seems to be among my favorites.

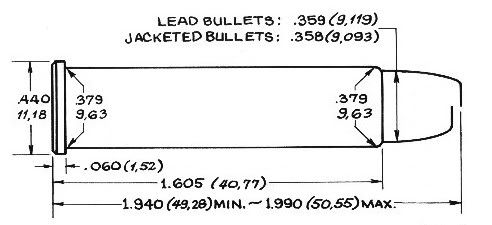

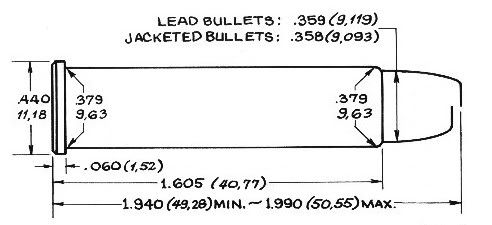

THE CARTRIDGE

Maybe this barrel is such a favorite because the cartridge for which it is chambered is so versatile. One can have loads ranging in power level from .38 Special to .35 Remington without difficulty.

The cartridge is an old one all done up in modern garb. You could trace it back to the .38 Ballard Extra Long. However, I think that all the developers of this round were doing was extending the .357 Magnum so that it was long enough to attain their goals. They had the silhouette game in mind and managed to convince Ruger to bring out a special revolver with a longer cylinder to handle it. That revolver was quickly taken off the market due to complaints of gas cutting of the frame above the cylinder/barrel gap. I've heard that there were 10,000 guns built so it must have had a market. I used to think a lot of the problem was reloader use of hot loads with light bullets, a use which was unanticipated and unintended. However, I read somewhere that Ruger asked Remington to modify the loading to reduce the problem but Remington would not (could not?) do it and Ruger pulled the model from the line. A friend who has one says that the erosion stopped at a certain point and he hasn't looked back. It seems that every collector has one and many have been used to create .445 SuperMag and other revolvers. Dan Wesson makes or made a revolver, but as with all their guns, the cylinder/barrel gap was adjustable and so could be minimized thus likewise minimizing the gas cutting "problem". TC apparently chambered for the cartridge pretty soon after it came out. It has been a moderate success there. NEF also chambered Handi-Rifles for the round but these have been discontinued. However, it is a simple matter to extend the chamber of the still manufactured .357 Magnum that little bit and it affects functioning not at all. Note: I now understand that NEF has discontinued the .357 Magnum rifles as well!

GENERAL LOADING NOTES

I am not particularly interested in silhouette shooting because there isn't a range in my area so all my loads are for hunting, and I generally practice with those same loads. This ensures that I don't have to change zero or that I don't forget to change zero. When I make up plinking or small game loads, I like for those loads to shoot to the sights at some distance without changing the zero from that of the "standard" ammunition.

I have a set procedure for reloading. I begin by taking all once fired cases and polishing them in my Frankfort Arsenal vibratory polisher. Then each case is run through the RCBS full-length sizing die (a carbide die, no lube required). All cases are trimmed to 1.600" after full-length resizing but before case mouth expansion/flaring. Immediately after trimming, cases are chamfered and then run through the case mouth expansion die. They are then primed. This leaves me with a batch that I can load during available time. It is my approach of having a batch of cases prepared for loading that causes me to prefer to use powders that don't require a different primer. I don't really care which it is, magnum or standard, but I'd prefer for it to be one or the other. Sometimes, such as with the .357 Max, I'll count out a certain number for use with one powder (H110 in this case) and prime with the CCI450s and then load that batch. Later I'll come back and prime the remainder with the CCI400 and load those with H4227 and a 200 gr. cast bullet.

There is a die "problem" some people experience when loading the Max. I made the mistake of loading my very first 180 gr. SSP in a .357 Max case using the seating stem that came with the die. The result was a flat point (FP). I had thought that I could get away with using the "issue" stem but it had flattened the point so much it was clear that would be unacceptable. So, I pulled the bullet (I like all mine to at least start out the same) and got the seating stem from my .35 Rem die, screwed it into the .357 Max die and seated a Hornady 180 gr. SSP just as pretty as pie. Too cheap to buy another seating stem, I just swap it back and forth.

That your dies will include a carbide sizer die is a great plus that many people overlook with this cartridge. No lubing is a time saver that I overlooked for many of my early years of reloading, but no longer.

BULLETS

There are 5 bullets that I've come to depend on for this cartridge. There are a couple that I might use given the need to. Shown in the accompanying photo, they are (from left to right): 158 gr. swaged Speer LSWC; 180 gr. Hornady SSP; 180 gr. Remington SJHP; 200 gr. Hornady RN; 205 gr. Leadheads FPGC; 200 gr. Cast Performance WLNGC. Although not illustrated, other suitable or popular bullets include the 180 gr. Hornady XTP, 150 gr. Corelokt SP, and the 180 gr. Speer FP.

The 158 gr. Speer LSWC is a swaged lead bullet. Originally intended for use in the .38 Special it performs very well in the Max when loaded to about 900-1100 fps. Such performance apparently duplicates the .38 Extra Long and doesn't strain the bullet. I did try the Hornady equivalent but didn't get nearly as good accuracy in my barrel in this application. Whether it was because one has to seat to crimp of the bore diameter portion of the bullet or the lube used by Hornady or some other unknown factor such as weight distribution in the bullet, I don't know. I do know that in my barrel, it is the Speer bullet that is the clear winner with groups more than an inch smaller at 50 yards.

The 180 gr. Hornady SSP has been a standard for me in this cartridge from the time I started to reload for it. I believe it was originally developed to provide optimum performance in .357 Herrett and .35 Remington barrels of 10-14 inches in length. I thought that it would be the perfect round in the smaller .357 Max case. Some do not experience good accuracy in their barrels but it performs better than or as well as any other bullet in my barrel and I don't think one can quibble with terminal performance on any game animal one would tackle with the Max. Note for those interested: That is the only SSP left in the line is the .358". The .308 and the .284 (we knew that the 7mm had been replaced by the VMAX) are gone. There is NO apparent replacement for the .30 cal SSP, however, MidwayUSA is still cataloging the .308 SSP.

The 200 gr. Hornady RN is a bullet that was built for one cartridge, the revered (at least by me) .35 Remington. It is an excellent bullet for the velocities produced by the Max, Herrett or Remington cartridges. Accuracy is right up there being 1.25" or less, seemingly with any load in any gun chambered for any of these three cartridges. I've got a lot of confidence in this bullet which has proven terminal performance. Now that I know that I can start it at velocities fully in excess of FACTORY .35 Remington loads, it may become a new standard with this cartridge.

Well, swaged bullets just don't get it for some people and jacketed bullets are "cheating" somehow so they love cast bullets in the Max. There are a couple that I think are "da bomb" in the Max.

The first is the Leadheads 205 gr. FPGC. I buy this bullet in 500 piece lots and have yet to have one I need to scrap. The excellent quality of this bullet from the folks at Leadheads (www.proshootpro.com) contributes to it's excellent accuracy and the design which follows those by Veral Smith works on game. I don't stress my cast bullets but this has a gas check and can be pushed just as fast as the Hornady jacketed bullet with the same load. It is still accurate and I like to use my load with this bullet for off-hand practice.

Perhaps with even better terminal performance on game is the Cast Performance 200 gr. WLNGC. Also a gas check design, this bullet can also be pushed to 2000 fps and is still accurate. No leading here. Cast Performance (www.castperformance.com) is another cast bullet maker with an excellent product. Never any scrap in their boxes but more than that, consistent weight and casting technique make for a consistently accurate bullet. It is a bit more expensive but the design is more along the lines of Veral Smith's thoughts and might be even more effective on game.

I should also talk about some bullets I don't use in the Max.

The 180 gr. XTP is NOT a bullet that I have used. Friends and acquaintances that have used it and posters to the various Internet forums often choose it as their premier bullet for the Max. I'm sure it is great in the revolvers chambered for the Max and probably solves whatever problem makes the SSP inaccurate in some barrels. It SHOULD be a good bullet for the Max and it certainly works well for quite a few people.

I only recently discovered the Remington 180 gr. SJHP. I've been told that this bullet was originally developed for the .357 Maximum. However, I've never seen it in loaded ammunition. In fact, the ONLY Remington factory ammo for the Max that I've ever seen is loaded with the 158 gr. SJHP. I bought 500 recently to use in a .357 Magnum rifle. They perform well there at about 1600 fps. Interestingly, that is about what you should get from the Max in a 10" barrel. I don't know how they would perform when launched at 2100 fps but they might be a bit frangible for my taste.

Indeed that's why I don't use the Remington 158 gr. SJHP. This bullet is all that I've seen loaded in the Remington factory ammo. As many gun-writers reported, this load is indeed more of a varmint load. Some people are very satisfied with the old Remington factory load with the 158 gr. SJHP on deer and some were not (very much not!). I think those differences of opinion are influenced by the size of deer shot and the ranges at which those deer were shot. Of course there are those who report that it takes deer down NOW. No doubt. However, I would bet that these fellows use it only on quartering shots from the rear and into the lungs just above the heart. The bullet is moving at 2173 fps from my 21" barrel and the bullet is just too "soft" for this starting velocity. Accurate, I don't use it on game larger than groundhogs. I would not recommend it be used on anything like coyote if you want the pelt. I think we can do better in this cartridge. Of course it will work on deer there and there isn't anything wrong with that if that is what you want. I want to be able to take game from any angle and prefer a sturdier bullet.

I think that the Remington 150 gr. Core-lokt SP deserves to be mentioned here. I think that this bullet is primarily designed to use in the .35 Remington. The intent being to provide greater velocities out of the old girl and flatten trajectories in the process. I'm sure that there are a lot of .357 Max Contender shooters out there using this bullet. Lighter by 30 whole grains than the 180s and with a sharp little point to boot one would think that this bullet can be driven fast and maintain that velocity way on out there (relatively speaking). There was even a fellow on the Accurate Reloading forum (www.accuratereloading.com) who prevailed upon Remington to make a run of 50,000 of these bullets and paid the up-front cost himself. Apparently, there were at least a few who agreed and I believe that he's recouped his investment. For me, these bullets were not at all accurate in my barrel. I believe that the bearing surface or perhaps that combined with the weight distribution of the bullet made this no better than a 2-3 inch grouper for me. For what it's worth, they don't work in my .35 Remingtons either!

The Speer 180 gr. FP was developed for use in the .35 Remington to give higher velocities and thus flatter trajectories with more bullet weight than the previous light bullet for the .35 Remington, the 150 gr. Corelokt SP. It is accurate in my barrel and it seems to provide good terminal performance but I thought that it might be a tad too heavily constructed to be used at the slightly slower Max velocities especially at the outer ranges at which I would use the cartridge. I don't experience the problems with accuracy with this, or any other 180 gr. bullet, that I had with the 150 gr. Remington. I do know of one shooter that uses this bullet exclusively, also from the carbine, and has excellent results on game deer sized and smaller.

One thing that some people don't consider when carrying loads of different capabilities. They often load the same bullets and can't tell the difference between loads when they get to the field. In the worst case a hunter might lose game due to misidentification of a small game load as a full-power "deer" load (or the other way round). Paint and fingernail polish sometimes can't be seen or wear off after extended carry. Much more certain in my opinion is to use a different bullet or different case. Cases can be differentiated by headstamp OR length (or both…). Bullets are much more certain. Usually, I load cast for the small game load and jacketed for the "deer" load. When using the heavy weight LBT style bullets, which are very effective, one needs to use a completely different style bullet to ensure that you can quickly tell the difference.

CRIMP

If you're talking bullets you've got to talk crimp. I've tried various degrees of crimp. In all cases consistent velocities are helped with a firm but not excessive roll crimp. I suppose that a good taper crimp would do as well, but my die is not a taper crimp die. I don't use the Lyman M die but do expand as I would with any straight case. I don't see anything "wrong" with any of the methods if they work. My system works and only because I take care to properly trim the cases and adjust the die. If you put too much of a roll in the roll-crimp your neck tension might actually decrease (with some dies) as the brass in the neck or case mouth is deformed. However, it seems that most of the powders indicated for the .357 Max are best served with quite a bit of resistance in the crimp. It is ALWAYS best for 2400 and H110/W296. Differences in the crimp often make a HUGE difference with H110/W296.

I'm not a "believer" in the factory crimp die concept and have none of those dies. I am satisfied with the performance of the crimp provided by my RCBS seating die.

TRIMMING

Trimming ensures that each case releases the bullets the same way. I have to admit, that for my first 600 rounds or so I didn't pay attention to trimming or the crimp. A few unexplainable flyers and sticky cases made me look at what was going on and the only variable is the crimp based on case length. When I eliminated that variable, the anomalies went away.

PRIMERS

This cartridge REQUIRES small RIFLE primers. Rifle primers are tougher and will withstand the 50,000 CUP that the .357 Max can go to. It IS stated to be a requirement for that reason. Clearly if you are loading to the old .38 Extra Long standard (i.e. 6 gr. Unique and a 150 gr. lead bullet) you won't have nearly the pressures. That's not what most do as that's not what the case was developed to do. I will reiterate, you must use small RIFLE primers. A pierced primer at these pressures in the gun you are using can be a very bad thing indeed. There is NO benefit to using small pistol primers. The cost to you of buying a $20 brick of primers is NOTHING compared to your EYESIGHT! (I've seen a couple of instances of the failure of protective eyewear. A fine safety element, NOTHING is guaranteed!)

POWDERS

I think that there is a wide range of powders usable in this case. However, there are relatively few powders that will produce the velocities (at safe pressures) for which the case was designed. WC680, AA1680, Lil'Gun, H110/W296, and H4227 seem to be best in my gun or are reported as providing the best velocities or accuracy in those guns shot by others.

BRASS

I've never seen the Federal or Winchester brass but I've accumulated over 1000 Remington cases. The Remington brass is pretty good, but when used in MY Contender barrel, it all needs to be precisely trimmed to 1.600 inches for best performance and there has been quite a bit of variance in length with this brass. Still, it holds up to repeated use well.

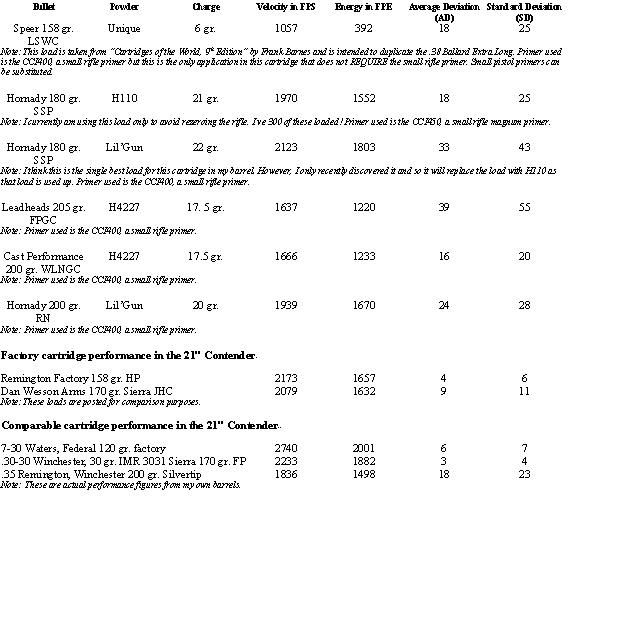

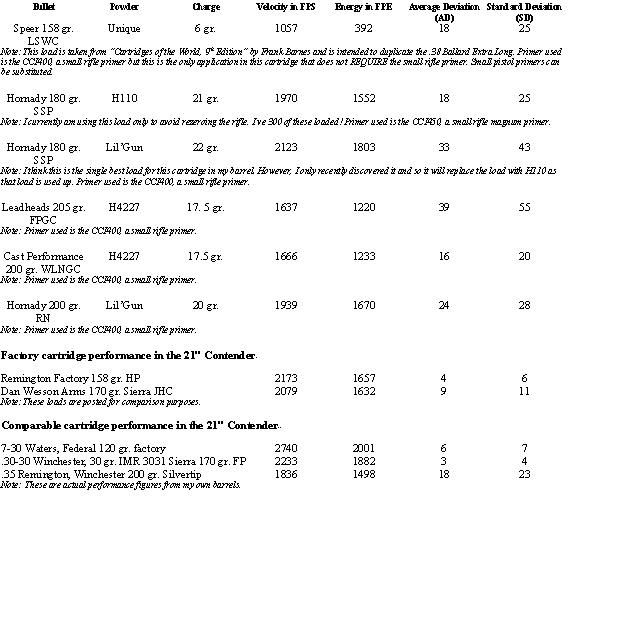

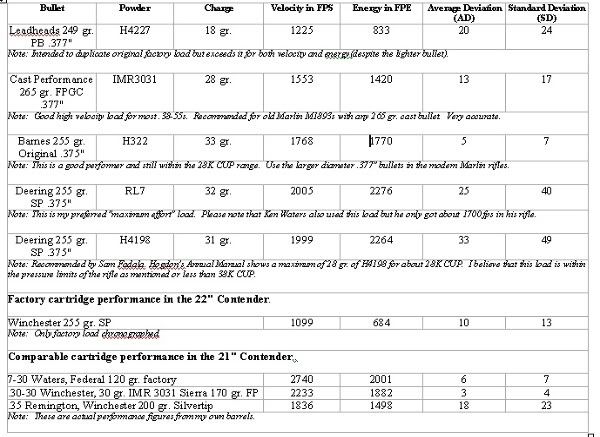

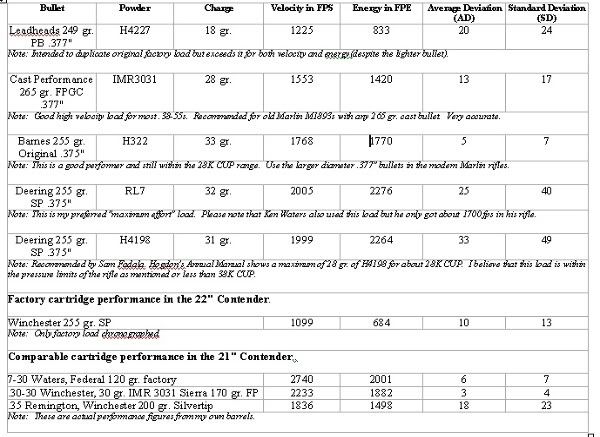

357 MAX LOAD DATA

The following chart gives my favorite loads. The "full effort" loads are the maximum in my barrel and I am not responsible for your use of this data or your reloading practices. It is your responsibility to use this data appropriately.

Of course one wants to see just how well this gun will shoot. By shooting the gun "off the bags" you'll have a better idea of how the gun really performs. It has been my experience that tip barrel rifles and the Contender in particular require that the resting point be to the rear of the pivot point with absolutely no upward pressure on the forearm. Shooting from field positions will give a better idea of how the gun groups when used in the field but the groups won't be as tight. This bothers some people but I use mine in the field, the range is only for load development. For those of you who care what MY rifle does, I'll tell you that from field positions I get 1-1½ inch groups at 100 yards with all but the 158 gr. Speer LSWC load. That load will do 1-1½ inches at 50 yards and requires but a small adjustment in point of aim. That's plenty for what I'm going to do and remember, these groups are shot from FIELD positions.

I've really grown to love this cartridge. It does what the .35 Remington does from factory loads and nearly what it will do from handloads. It also has some advantages. Rimmed case for ease in handling with the Contender, a straight case that can be reloaded using a carbide sizing die eases reloading chores, and a small case head that increases the margin of safety in the Contender system. It is that small case head that allows the 50K CUP pressures that allow, in turn, the .357 Maximum to run so closely on the heels of the .35 Remington. Another benefit to many is that the Max can do this on very light charges, one-half to two-thirds of what the .35 Remington will use. With powder prices rising, this is important to quite a few shooters.

Light powder charges do something other than ease the strain on the wallet. They reduce recoil as well. Recoil with the heaviest charges and bullets have a recoil energy of only 13.7 ft lbs. That's actually 3 ft lbs. less than the .35 Remington 200 gr. factory load at only 1836 fps. This gun is easy on you all the way round!

However, there are those who always push too hard. You will see some who claim that they get 200 gr. RNs to 2000 fps in 18" or shorter barrels. They have to really be pushing things even using 680, AA1680 or Lil'Gun. I don't think it is worth losing your eyesight (or worse). There are limits to everything. If you simply must have more velocity, chamber for a bigger case like the .358 JDJ or .358 Bellm.

Wanting a small game load for my barrel, I tried 2.5 gr. of Bullseye in the .38 Spec case with the 205 gr. cast bullet. This makes a quiet (not silent) small game load that shoots point of aim at 50 yards when the gun is sighted for 100 yards using the full-power loads. Very handy and you can easily tell them apart. A nearly silent small game load would be a great benefit in some circumstances.

This is an efficient, well-balanced cartridge that gets .30-30 performance without a lot of powder. It will match factory .35 Remington ammo. I like it.

Addendum--

We are constantly asked about adaptation of this cartridge to lever-action and other rifles. Most of these requests for detailed information are without any research what-so-ever. However, in the interest of saving me some typing in the future I'm going to add it here.

The Marlin 1894 is most often mentioned as the "ideal" basis for a rifle chambering this cartridge. It isn't. One shooter actually had a very good smith make up such a rifle. He reported that he wasn't entirely satisfied with it. Functioning wasn't entirely reliable and the lever throw had to be so lengthened that use of the gun was awkward. He felt that the awkwardly long lever throw might have contributed to the functioning problems but that the geometry inside the action as the overly long for this action cartridge was maneuvered into position must have contributed to his problems.

The Marlin 336 is simply too long an action for the .357 Maximum. The same problems that the .44 Magnum 336s sometimes had can occur with the Max. Further, a new barrel is required. One can't simply re-chamber a .35 Remington barrel (and one wonders why one would). This increases the cost considerably. This gun also negates the smaller action/lighter weight rifle benefit one expects with the .357 Maximum.

Another action mentioned is the Winchester 1894/94 as one might expect. After all, the action is one of the most common available. The MOST suitable of these is those guns factory produced in .357 Magnum. Some shooters have reported that these will already handle the .360 Dan Wesson cartridge which splits the difference between the .357 Mag and the .357 Max. Still, one shooter who actually attempted the conversion wasn't, at last report, fully satisfied with functioning. Apparently the cartridge guides are set up to handle the .357 Mag length cartridge and while they actually will work with the .360 DW don't work with the Max. Altering the cartridge guides takes time (and money) to do correctly.

The Winchester 1892 and clones are simply too small to handle the additional length of the .357 Maximum cartridge.

Also asked is why there are no factory chambered leverguns for the .357 Max. The simple explanation is that there is no market. Many shooters have found that the cartridge is wonderful in single-shots. One can load about any bullet. It is easy to reload (no lubing of cases).

THE GUN

My .357 Max is a factory, 21", blue, Contender purchased from the old TC Arms obsolete barrel list for $113.50 plus shipping. I like it. My thanks to all on the old TC-List for that tip. I don't know what the twist rate is, but I think it is the same as the .35 Rem, at least in the factory barrels.

I've mounted a Weaver 2½X fixed power scope in a Leupold mount. This scope has a duplex reticule. Now some may wonder at the low magnification of this scope but it suites me. Given the cartridge's capabilities, there is no need for more magnification.

It is stocked in factory Rynite. Rynite is a synthetic stock material and the stocks are made by Choate Machine and Tool Company (www.riflestock.com) for Thompson Center Arms. I like the combination of appearance (I'm used to synthetics from my military service) and light weight compared to wood. I also think that the Rynite stocks fit me better than the wood provided by TCA. Thus the gun all up (sling TOO) and loaded weighs just 6¼ lbs. That's not too much to pack for anyone.

As I write this I have 21 barrels of which only 2 are the 10" length. All others are 16" and longer and the cartridges for which they are chambered range from the .22 LR to 28 gauge shotgun. This barrel, chambered for the .357 Remington Maximum, seems to be among my favorites.

THE CARTRIDGE

Maybe this barrel is such a favorite because the cartridge for which it is chambered is so versatile. One can have loads ranging in power level from .38 Special to .35 Remington without difficulty.

The cartridge is an old one all done up in modern garb. You could trace it back to the .38 Ballard Extra Long. However, I think that all the developers of this round were doing was extending the .357 Magnum so that it was long enough to attain their goals. They had the silhouette game in mind and managed to convince Ruger to bring out a special revolver with a longer cylinder to handle it. That revolver was quickly taken off the market due to complaints of gas cutting of the frame above the cylinder/barrel gap. I've heard that there were 10,000 guns built so it must have had a market. I used to think a lot of the problem was reloader use of hot loads with light bullets, a use which was unanticipated and unintended. However, I read somewhere that Ruger asked Remington to modify the loading to reduce the problem but Remington would not (could not?) do it and Ruger pulled the model from the line. A friend who has one says that the erosion stopped at a certain point and he hasn't looked back. It seems that every collector has one and many have been used to create .445 SuperMag and other revolvers. Dan Wesson makes or made a revolver, but as with all their guns, the cylinder/barrel gap was adjustable and so could be minimized thus likewise minimizing the gas cutting "problem". TC apparently chambered for the cartridge pretty soon after it came out. It has been a moderate success there. NEF also chambered Handi-Rifles for the round but these have been discontinued. However, it is a simple matter to extend the chamber of the still manufactured .357 Magnum that little bit and it affects functioning not at all. Note: I now understand that NEF has discontinued the .357 Magnum rifles as well!

GENERAL LOADING NOTES

I am not particularly interested in silhouette shooting because there isn't a range in my area so all my loads are for hunting, and I generally practice with those same loads. This ensures that I don't have to change zero or that I don't forget to change zero. When I make up plinking or small game loads, I like for those loads to shoot to the sights at some distance without changing the zero from that of the "standard" ammunition.

I have a set procedure for reloading. I begin by taking all once fired cases and polishing them in my Frankfort Arsenal vibratory polisher. Then each case is run through the RCBS full-length sizing die (a carbide die, no lube required). All cases are trimmed to 1.600" after full-length resizing but before case mouth expansion/flaring. Immediately after trimming, cases are chamfered and then run through the case mouth expansion die. They are then primed. This leaves me with a batch that I can load during available time. It is my approach of having a batch of cases prepared for loading that causes me to prefer to use powders that don't require a different primer. I don't really care which it is, magnum or standard, but I'd prefer for it to be one or the other. Sometimes, such as with the .357 Max, I'll count out a certain number for use with one powder (H110 in this case) and prime with the CCI450s and then load that batch. Later I'll come back and prime the remainder with the CCI400 and load those with H4227 and a 200 gr. cast bullet.

There is a die "problem" some people experience when loading the Max. I made the mistake of loading my very first 180 gr. SSP in a .357 Max case using the seating stem that came with the die. The result was a flat point (FP). I had thought that I could get away with using the "issue" stem but it had flattened the point so much it was clear that would be unacceptable. So, I pulled the bullet (I like all mine to at least start out the same) and got the seating stem from my .35 Rem die, screwed it into the .357 Max die and seated a Hornady 180 gr. SSP just as pretty as pie. Too cheap to buy another seating stem, I just swap it back and forth.

That your dies will include a carbide sizer die is a great plus that many people overlook with this cartridge. No lubing is a time saver that I overlooked for many of my early years of reloading, but no longer.

BULLETS

There are 5 bullets that I've come to depend on for this cartridge. There are a couple that I might use given the need to. Shown in the accompanying photo, they are (from left to right): 158 gr. swaged Speer LSWC; 180 gr. Hornady SSP; 180 gr. Remington SJHP; 200 gr. Hornady RN; 205 gr. Leadheads FPGC; 200 gr. Cast Performance WLNGC. Although not illustrated, other suitable or popular bullets include the 180 gr. Hornady XTP, 150 gr. Corelokt SP, and the 180 gr. Speer FP.

The 158 gr. Speer LSWC is a swaged lead bullet. Originally intended for use in the .38 Special it performs very well in the Max when loaded to about 900-1100 fps. Such performance apparently duplicates the .38 Extra Long and doesn't strain the bullet. I did try the Hornady equivalent but didn't get nearly as good accuracy in my barrel in this application. Whether it was because one has to seat to crimp of the bore diameter portion of the bullet or the lube used by Hornady or some other unknown factor such as weight distribution in the bullet, I don't know. I do know that in my barrel, it is the Speer bullet that is the clear winner with groups more than an inch smaller at 50 yards.

The 180 gr. Hornady SSP has been a standard for me in this cartridge from the time I started to reload for it. I believe it was originally developed to provide optimum performance in .357 Herrett and .35 Remington barrels of 10-14 inches in length. I thought that it would be the perfect round in the smaller .357 Max case. Some do not experience good accuracy in their barrels but it performs better than or as well as any other bullet in my barrel and I don't think one can quibble with terminal performance on any game animal one would tackle with the Max. Note for those interested: That is the only SSP left in the line is the .358". The .308 and the .284 (we knew that the 7mm had been replaced by the VMAX) are gone. There is NO apparent replacement for the .30 cal SSP, however, MidwayUSA is still cataloging the .308 SSP.

The 200 gr. Hornady RN is a bullet that was built for one cartridge, the revered (at least by me) .35 Remington. It is an excellent bullet for the velocities produced by the Max, Herrett or Remington cartridges. Accuracy is right up there being 1.25" or less, seemingly with any load in any gun chambered for any of these three cartridges. I've got a lot of confidence in this bullet which has proven terminal performance. Now that I know that I can start it at velocities fully in excess of FACTORY .35 Remington loads, it may become a new standard with this cartridge.

Well, swaged bullets just don't get it for some people and jacketed bullets are "cheating" somehow so they love cast bullets in the Max. There are a couple that I think are "da bomb" in the Max.

The first is the Leadheads 205 gr. FPGC. I buy this bullet in 500 piece lots and have yet to have one I need to scrap. The excellent quality of this bullet from the folks at Leadheads (www.proshootpro.com) contributes to it's excellent accuracy and the design which follows those by Veral Smith works on game. I don't stress my cast bullets but this has a gas check and can be pushed just as fast as the Hornady jacketed bullet with the same load. It is still accurate and I like to use my load with this bullet for off-hand practice.

Perhaps with even better terminal performance on game is the Cast Performance 200 gr. WLNGC. Also a gas check design, this bullet can also be pushed to 2000 fps and is still accurate. No leading here. Cast Performance (www.castperformance.com) is another cast bullet maker with an excellent product. Never any scrap in their boxes but more than that, consistent weight and casting technique make for a consistently accurate bullet. It is a bit more expensive but the design is more along the lines of Veral Smith's thoughts and might be even more effective on game.

I should also talk about some bullets I don't use in the Max.

The 180 gr. XTP is NOT a bullet that I have used. Friends and acquaintances that have used it and posters to the various Internet forums often choose it as their premier bullet for the Max. I'm sure it is great in the revolvers chambered for the Max and probably solves whatever problem makes the SSP inaccurate in some barrels. It SHOULD be a good bullet for the Max and it certainly works well for quite a few people.

I only recently discovered the Remington 180 gr. SJHP. I've been told that this bullet was originally developed for the .357 Maximum. However, I've never seen it in loaded ammunition. In fact, the ONLY Remington factory ammo for the Max that I've ever seen is loaded with the 158 gr. SJHP. I bought 500 recently to use in a .357 Magnum rifle. They perform well there at about 1600 fps. Interestingly, that is about what you should get from the Max in a 10" barrel. I don't know how they would perform when launched at 2100 fps but they might be a bit frangible for my taste.

Indeed that's why I don't use the Remington 158 gr. SJHP. This bullet is all that I've seen loaded in the Remington factory ammo. As many gun-writers reported, this load is indeed more of a varmint load. Some people are very satisfied with the old Remington factory load with the 158 gr. SJHP on deer and some were not (very much not!). I think those differences of opinion are influenced by the size of deer shot and the ranges at which those deer were shot. Of course there are those who report that it takes deer down NOW. No doubt. However, I would bet that these fellows use it only on quartering shots from the rear and into the lungs just above the heart. The bullet is moving at 2173 fps from my 21" barrel and the bullet is just too "soft" for this starting velocity. Accurate, I don't use it on game larger than groundhogs. I would not recommend it be used on anything like coyote if you want the pelt. I think we can do better in this cartridge. Of course it will work on deer there and there isn't anything wrong with that if that is what you want. I want to be able to take game from any angle and prefer a sturdier bullet.

I think that the Remington 150 gr. Core-lokt SP deserves to be mentioned here. I think that this bullet is primarily designed to use in the .35 Remington. The intent being to provide greater velocities out of the old girl and flatten trajectories in the process. I'm sure that there are a lot of .357 Max Contender shooters out there using this bullet. Lighter by 30 whole grains than the 180s and with a sharp little point to boot one would think that this bullet can be driven fast and maintain that velocity way on out there (relatively speaking). There was even a fellow on the Accurate Reloading forum (www.accuratereloading.com) who prevailed upon Remington to make a run of 50,000 of these bullets and paid the up-front cost himself. Apparently, there were at least a few who agreed and I believe that he's recouped his investment. For me, these bullets were not at all accurate in my barrel. I believe that the bearing surface or perhaps that combined with the weight distribution of the bullet made this no better than a 2-3 inch grouper for me. For what it's worth, they don't work in my .35 Remingtons either!

The Speer 180 gr. FP was developed for use in the .35 Remington to give higher velocities and thus flatter trajectories with more bullet weight than the previous light bullet for the .35 Remington, the 150 gr. Corelokt SP. It is accurate in my barrel and it seems to provide good terminal performance but I thought that it might be a tad too heavily constructed to be used at the slightly slower Max velocities especially at the outer ranges at which I would use the cartridge. I don't experience the problems with accuracy with this, or any other 180 gr. bullet, that I had with the 150 gr. Remington. I do know of one shooter that uses this bullet exclusively, also from the carbine, and has excellent results on game deer sized and smaller.

One thing that some people don't consider when carrying loads of different capabilities. They often load the same bullets and can't tell the difference between loads when they get to the field. In the worst case a hunter might lose game due to misidentification of a small game load as a full-power "deer" load (or the other way round). Paint and fingernail polish sometimes can't be seen or wear off after extended carry. Much more certain in my opinion is to use a different bullet or different case. Cases can be differentiated by headstamp OR length (or both…). Bullets are much more certain. Usually, I load cast for the small game load and jacketed for the "deer" load. When using the heavy weight LBT style bullets, which are very effective, one needs to use a completely different style bullet to ensure that you can quickly tell the difference.

CRIMP

If you're talking bullets you've got to talk crimp. I've tried various degrees of crimp. In all cases consistent velocities are helped with a firm but not excessive roll crimp. I suppose that a good taper crimp would do as well, but my die is not a taper crimp die. I don't use the Lyman M die but do expand as I would with any straight case. I don't see anything "wrong" with any of the methods if they work. My system works and only because I take care to properly trim the cases and adjust the die. If you put too much of a roll in the roll-crimp your neck tension might actually decrease (with some dies) as the brass in the neck or case mouth is deformed. However, it seems that most of the powders indicated for the .357 Max are best served with quite a bit of resistance in the crimp. It is ALWAYS best for 2400 and H110/W296. Differences in the crimp often make a HUGE difference with H110/W296.

I'm not a "believer" in the factory crimp die concept and have none of those dies. I am satisfied with the performance of the crimp provided by my RCBS seating die.

TRIMMING

Trimming ensures that each case releases the bullets the same way. I have to admit, that for my first 600 rounds or so I didn't pay attention to trimming or the crimp. A few unexplainable flyers and sticky cases made me look at what was going on and the only variable is the crimp based on case length. When I eliminated that variable, the anomalies went away.

PRIMERS

This cartridge REQUIRES small RIFLE primers. Rifle primers are tougher and will withstand the 50,000 CUP that the .357 Max can go to. It IS stated to be a requirement for that reason. Clearly if you are loading to the old .38 Extra Long standard (i.e. 6 gr. Unique and a 150 gr. lead bullet) you won't have nearly the pressures. That's not what most do as that's not what the case was developed to do. I will reiterate, you must use small RIFLE primers. A pierced primer at these pressures in the gun you are using can be a very bad thing indeed. There is NO benefit to using small pistol primers. The cost to you of buying a $20 brick of primers is NOTHING compared to your EYESIGHT! (I've seen a couple of instances of the failure of protective eyewear. A fine safety element, NOTHING is guaranteed!)

POWDERS

I think that there is a wide range of powders usable in this case. However, there are relatively few powders that will produce the velocities (at safe pressures) for which the case was designed. WC680, AA1680, Lil'Gun, H110/W296, and H4227 seem to be best in my gun or are reported as providing the best velocities or accuracy in those guns shot by others.

BRASS

I've never seen the Federal or Winchester brass but I've accumulated over 1000 Remington cases. The Remington brass is pretty good, but when used in MY Contender barrel, it all needs to be precisely trimmed to 1.600 inches for best performance and there has been quite a bit of variance in length with this brass. Still, it holds up to repeated use well.

357 MAX LOAD DATA

The following chart gives my favorite loads. The "full effort" loads are the maximum in my barrel and I am not responsible for your use of this data or your reloading practices. It is your responsibility to use this data appropriately.

Of course one wants to see just how well this gun will shoot. By shooting the gun "off the bags" you'll have a better idea of how the gun really performs. It has been my experience that tip barrel rifles and the Contender in particular require that the resting point be to the rear of the pivot point with absolutely no upward pressure on the forearm. Shooting from field positions will give a better idea of how the gun groups when used in the field but the groups won't be as tight. This bothers some people but I use mine in the field, the range is only for load development. For those of you who care what MY rifle does, I'll tell you that from field positions I get 1-1½ inch groups at 100 yards with all but the 158 gr. Speer LSWC load. That load will do 1-1½ inches at 50 yards and requires but a small adjustment in point of aim. That's plenty for what I'm going to do and remember, these groups are shot from FIELD positions.

I've really grown to love this cartridge. It does what the .35 Remington does from factory loads and nearly what it will do from handloads. It also has some advantages. Rimmed case for ease in handling with the Contender, a straight case that can be reloaded using a carbide sizing die eases reloading chores, and a small case head that increases the margin of safety in the Contender system. It is that small case head that allows the 50K CUP pressures that allow, in turn, the .357 Maximum to run so closely on the heels of the .35 Remington. Another benefit to many is that the Max can do this on very light charges, one-half to two-thirds of what the .35 Remington will use. With powder prices rising, this is important to quite a few shooters.

Light powder charges do something other than ease the strain on the wallet. They reduce recoil as well. Recoil with the heaviest charges and bullets have a recoil energy of only 13.7 ft lbs. That's actually 3 ft lbs. less than the .35 Remington 200 gr. factory load at only 1836 fps. This gun is easy on you all the way round!