There is one topic that arises frequently on internet firearms forums/chat rooms particularly those devoted to Marlins, leveractions or handloading. That subject is the rechambering of the Marlin 336 in .30-30 (.30 WCF) to .307 or .308 Winchester and/or the rechambering of the 336 in .35 Remington to .356 or .358 Winchester. It has been encouraged by articles such as this one, Damaged Marlin 336 Restored, Rechambered for .358 Winchester by R. K. Campbell. It isn't my intention to discuss Mr. Campbell's article but rather to dispute the assertions made by many who apparently misread his article.

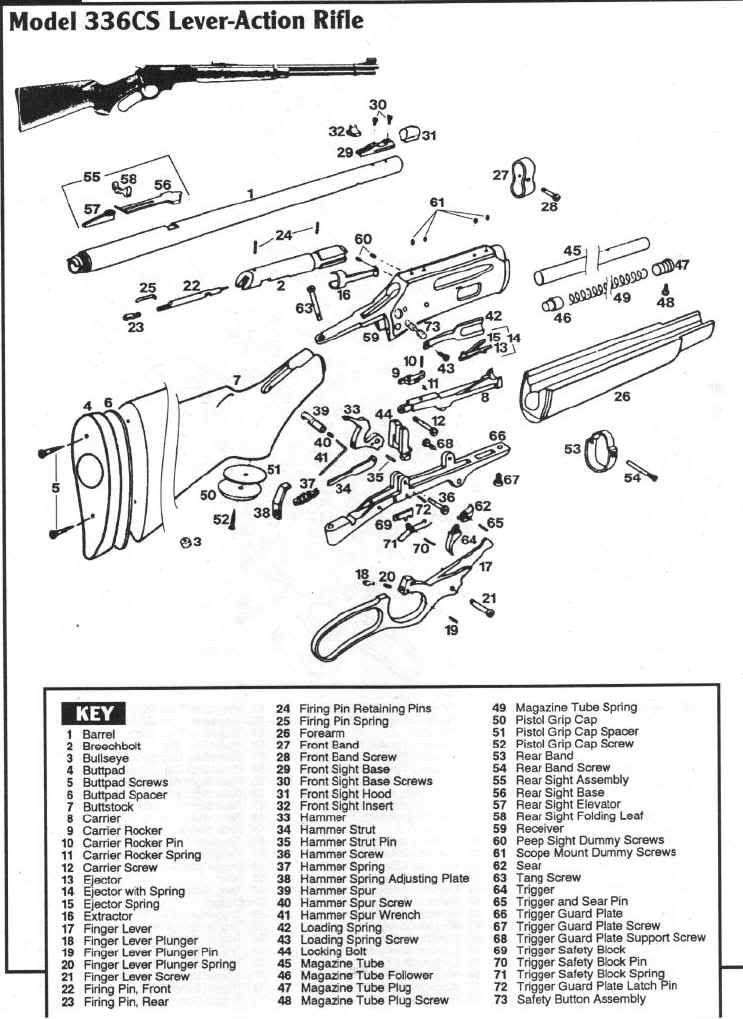

There is one topic that arises frequently on internet firearms forums/chat rooms particularly those devoted to Marlins, leveractions or handloading. That subject is the rechambering of the Marlin 336 in .30-30 (.30 WCF) to .307 or .308 Winchester and/or the rechambering of the 336 in .35 Remington to .356 or .358 Winchester. It has been encouraged by articles such as this one, Damaged Marlin 336 Restored, Rechambered for .358 Winchester by R. K. Campbell. It isn't my intention to discuss Mr. Campbell's article but rather to dispute the assertions made by many who apparently misread his article.The goal, almost universally, is to get "better" ballistics easily and cheaply. Easily because the conversion will require "only" running a chambering reamer into the action and cheaply because the owner can do it himself without removing the barrel or using power tools. Ignored in the conversions .35 Rem to .356/.358 Win are the need, in some instances at least, to change the .35 Rem bolt for a .30-30 bolt to handle the rim of the new round. Ignored too, is the ability of the action to handle the increased case/cartridge length. Some will point out that the action can be modified to handle a cartridge up to 2.665" COL but that negates the "easy" and "cheap" part of the conversion, at least for most shooters.

Posters define better ballistics as flatter trajectory or more usually "more knockdown", i.e. more energy. Sometimes, those expectations are unrealistic. Posters often point to the ballistics of the wished for round ignoring the fact that until Hornady releases the LEVERevolution© bullets, the pointed high ballistic coefficient (BC) bullets used in the ballistic tables can't be used in the tubular magazine of the 336 due to safety concerns. Indeed the loaded cartridges will be too long to feed in the rifle. Larger cartridges are necessary to the concept of increased ballistic performance. If you can't fit the loaded cartridge into the gun and have it function in the gun, the whole idea is a waste of time. Mr. Campbell, although he shows factory ammo ballistics in the table in his article, acknowledges this problem of fit by only loading the .358 in the rechambered gun with pistol bullets. Only pistol bullets have the flat point, overall length, and cannelure position to permit use in the 336 as it is. Thus, the ballistics in the table are misleading and boy, are people mislead. Also ignored is that the barrel length used for the ballistics tables quoted are longer for the conversion cartridges than they are for the standard 336 carbine length of 20".

For many years the ballistics of the .30 WCF and .35 Remington were considered more than adequate. Indeed they were an improvement over older black powder cartridges providing adequate power fired from compact platforms. They were even commonly used on elk and other large game. After WWI and WWII, the bolt action and .30-06 cartridge and larger began to dominate the game fields. Marketing made many hunters doubt this well established cartridges. The .30 WCF and .35 Rem produced their ballistics, 170 and 200 gr. bullets respectively at 2200 fps, generating about 38-40,000 PSI or a breach thrust of about 4800 psi for the .30 WCF, 4900 psi and for the .35 Rem. This was well within the capabilities of the actions in which these cartridges were chambered including the 336 Marlin.

For many years the ballistics of the .30 WCF and .35 Remington were considered more than adequate. Indeed they were an improvement over older black powder cartridges providing adequate power fired from compact platforms. They were even commonly used on elk and other large game. After WWI and WWII, the bolt action and .30-06 cartridge and larger began to dominate the game fields. Marketing made many hunters doubt this well established cartridges. The .30 WCF and .35 Rem produced their ballistics, 170 and 200 gr. bullets respectively at 2200 fps, generating about 38-40,000 PSI or a breach thrust of about 4800 psi for the .30 WCF, 4900 psi and for the .35 Rem. This was well within the capabilities of the actions in which these cartridges were chambered including the 336 Marlin.On the other hand, the .308 and .358 Winchester generate their ballistics, using 180 and 200 gr. bullets respectively, with pressures of about 52,000 PSI and breach thrust of approximately 8400 psi for the .358 Winchester. This is due to the larger case base and much higher pressure. So, as you can see, it is inevitable that a lot of the discussion concerns the strength of the 336 action. I'll talk about that a bit later.

Is there an overwhelming ballistic advantage? I don't think so. The .35 Rem can easily be loaded to move the 200 gr. RN to about 2200 fps and the 220 gr. Speer can be loaded to go about 2000 fps. The .358 is said to push those bullets to about 2500 fps but those figures come from 24" barrels. I think that 2400 fps is closer to realistic or only about 200 fps faster. The .356 will go about 2350 fps for the same bullet from the 20" barrel.

Proponents of the conversions point to the factory chambering by Marlin of the rifle to .375 Winchester which has a SAAMI average maximum or working pressure of 52,000 PSI. They ignore the fact that the .375 case is nearly straight and that it has the smaller .30 WCF case head and that the case has extra thick case walls as do the .307 and .356 Winchester. I think that perhaps the case walls have the complimentary effects of reducing the case expansion and decreasing the effective case head size both of which reduce breach thrust.

Proponents of the conversions point to the factory chambering by Marlin of the rifle to .375 Winchester which has a SAAMI average maximum or working pressure of 52,000 PSI. They ignore the fact that the .375 case is nearly straight and that it has the smaller .30 WCF case head and that the case has extra thick case walls as do the .307 and .356 Winchester. I think that perhaps the case walls have the complimentary effects of reducing the case expansion and decreasing the effective case head size both of which reduce breach thrust.Some folks have pointed to the "fact" that Marlins don't fail at the locking bolt but the receiver distorts and then lets go as shown in the last photo. Indeed that was the context in which I found that photo. I wonder, how important is how the action fails?

In attempting to dissuade us from the breach thrust argument, some remind us of P. O. Ackley's experiments where he moved the locking bolts from guns chambered for his improved .30-30 and there was no problem, presumably because there is no bolt thrust. However, in the context of Contenders, his protege Mike Bellm has made it clear that all cartridges produce breach thrust. He also feels that the .375 Winchester's case design as well as the .307 and .356 help to mitigate that breach thrust. I would like to point out that the Winchester company modified their M94 in order to use these cartridges. Marlin did not but produced NO .307s and only some 2000 .356s. They have NEVER produced or attempted to produce guns chambered for the .308 or .358 Winchester cartridges. Methinks that there is a reason and it wasn't some perceived inability to handle rimless cases as the 336 does very well with the rimless .35 Remington.

In attempting to dissuade us from the breach thrust argument, some remind us of P. O. Ackley's experiments where he moved the locking bolts from guns chambered for his improved .30-30 and there was no problem, presumably because there is no bolt thrust. However, in the context of Contenders, his protege Mike Bellm has made it clear that all cartridges produce breach thrust. He also feels that the .375 Winchester's case design as well as the .307 and .356 help to mitigate that breach thrust. I would like to point out that the Winchester company modified their M94 in order to use these cartridges. Marlin did not but produced NO .307s and only some 2000 .356s. They have NEVER produced or attempted to produce guns chambered for the .308 or .358 Winchester cartridges. Methinks that there is a reason and it wasn't some perceived inability to handle rimless cases as the 336 does very well with the rimless .35 Remington.Pressure is important. It affects shooting in three important ways. The first of course is that it pushes the bullet down the bore. So far, so good. It also bears on gun design.

- The first way is that the gun must have sufficient hoop strength to contain the pressure generated in firing. This is why a minimum thickness of any particular metal is required over the chamber and bore. Obviously, a margin of safety, extra strength if you will, is necessary. I submit that there is no margin of safety or that it has been seriously reduced by use of cartridges generating 52,000 PSI with a case diameter the same as the .444 Marlin (limited to about 42,000 PSI).

- The second consideration is breach thrust. That is the pressure that bears against the bolt and through the bolt to the locking lugs or bolts on a rifle action. You can figure that by dividing the pressure in PSI by the internal area of the case base. In my mind this is the important issue. How this will wear the gun, stretch the parts to the point of unserviceability, accelerate other wear, and so forth is a genuine concern for me.

Debate also rages about whether or not the 336 actions were heat treated differently for the various cartridges, TomRay (a Marlin employee) has stated that he isn't aware of different heat treating for the different actions. This makes sense as it is a costly thing to have to produce actions which are cartridge specific. TomRay has also mentioned that the .356 rifles (the 336 ER) that Marlin produced required tighter than normal breaching to work correctly and that the locking bolt must fit the action to produce a very tight lock up. How many shade tree gunsmiths are going to be able to do this? Why would you want to produce a rifle with no ballistic advantage and lower resale (if you can sell it) value? NOTE: TomRay also says not to take his "speculation" as true.

Tim Looney at Marlin is quoted as saying that the differences between the .35 Rem and .356 Winchester barrels are:

- .35 Remington barrel: Bore: .3500" Groove: .3570" Grooves: 6 Twist rate: 1 x 16 RH

- .356 Winchester barrel: Bore: .3515"Groove: .3577" Grooves: 6 Twist rate: 1 x 12 RH

Mr. M. L. McPherson has contemplated what can be done with the Marlin action. His article, "What is Possible with the Marlin" is an excellent read which will likely interest anyone struggling with my poor writing here.

|

| 1895 Action |

3 comments:

I accept the 35 Remington ballistics as adequate for my hunting/targeting purposes.

I plan to improve my rifle to accept the 358 Winchester nonetheless.

My desire is to make my rifle accept this cartridge solely for what I deem as superior geometrical design.

But I intend to load the 358 Winchester cartridge ONLY to the maximum loads of the 35 Remington.

It is uncertain what modifications, beyond rechambering, are required.

I would appreciate advice on the merits of this project

That you don't know what other changes beyond rechambering are required demonstrates an ignorance of the subject that ill serves your goals.

You will not be able to run cartridges with 200 gr. bullets seated correctly through the action. This is because this action is set up to run a cartridge of a certain maximum LOA. There are ways around this, one of which is to use light for the cartridge PISTOL bullets. That subject has been mentioned above.

You will need more powder to run the same bullets at the same velocities as in the smaller .35 Rem case.

Most importantly, to me, is that you will be creating a hazard to future shooters who get your rifle. We can be certain, absolutely certain, that someday you'll die and somebody, probably ignorant of the limits of the action, will get your rifle. If they are really smart/aware and fortunate they will be able to spend half the value of the rifle in returning it to the original chambering.

You would be ahead to get a .358 Winchester rifle and load it down to .35 Rem levels. Then you will have the superior cartridge form you prefer and will risk nobody in the future.

Hobie, thanks for your analysis on this topic. While its seven years later, it gave me something to consider. I am about to purchase a 336-35 rem converted to .358. I will have it checked for previous over stressing. I plan on using the rcbs 200 gr bullet and using quickload to keep the pressure at an acceptable level.

The idea of someone loading high pressure loads in it has made me decide to will it to a much younger man who is knowledgeable about its limitations.

Post a Comment